LessLoss Firewall and Tunnelbridge: progress reportTuesday 01 February, 2011

Hi,

I have some new pictures of some of the work that has been put into the production of the Firewall.

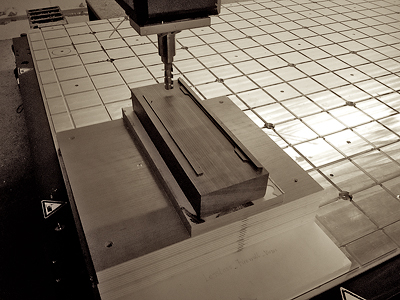

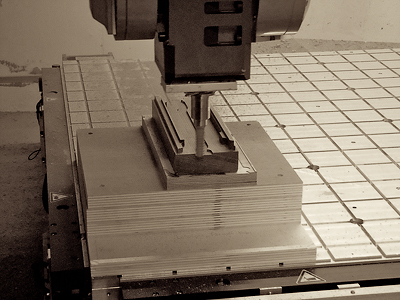

Above you see a heavy Panzerholz block, which, after milling, polishing, and oiling, will form one half of the Firewall’s Panzerholz casing. The precise milling process requires special diamond tooling (not available at Lowe’s or Home Depot). The tools spin so quickly that the requirements for centering them into the spindle would not be met with a mechanical screw-type fastener. The technology here is different: the fastener which holds the tools is heated up until the metal expands far enough for the tool to enter. When the metal cools, it contracts slightly, and thus holds the tool exactly in place, exactly centered. If the tools were just a little bit off center, they would immediately overheat due to their operational speed.

The milling machine is computer controlled. The operators have to spend many man-hours programming what is called the strategy. The strategy is the determination of efficient movements of the spindle to create the forms in the least amount of time. But other considerations must be made as well, such as the heat dispersion of the material being milled. Panzerholz is a very poor conductor of heat, thus placing precise speed prerequisites upon efficiency of progress. Too slow, and everything overheats. Too fast, and again the same happens. There is only one optimum speed, and this varies according to the amount of ‘bite’ of the tools used. Other considerations include the angles and directions at which the entrances and exists are made at each pass. Wood is more difficult to work than aluminum. Even if Panzerholz is more dense, it is still a natural product and thus not entirely homogenous.

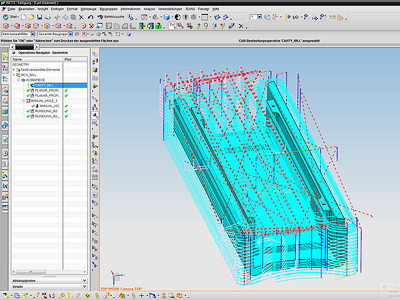

Above, the red dotted lines depict the programmed strategy. The machine and software used on this project cost just under a million Euros. Micro-vibrations are a big issue when working with high speed milling machinery, and these are addressed in the following way:

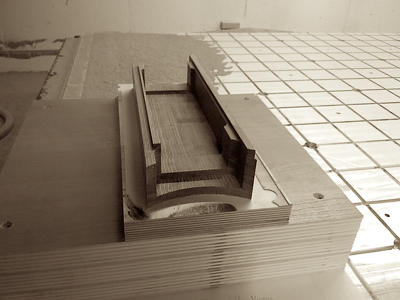

Above is pictured the ‘shock absorber’ solution employed. Through the use of multiple layers of hardwood, ample vibration control is achieved for the reliability of continuous highly precise results.

One would think that it is ‘just a robot’ and that automated processes are among the least expensive possible production methods. Even with the high technologies implemented in the creation of the Panzerholz parts, what you see above, that is, merely the internal milling of one half of the Firewall’s Panzerholz parts, without even the outer curvatures, takes one full hour. You are invited to view an excerpt of the production process right here.

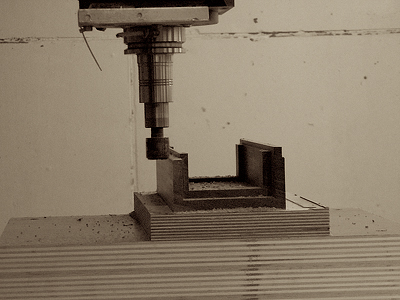

Here we see a smaller tool finishing up some of the more detailed intricacies towards the end of this milling process.

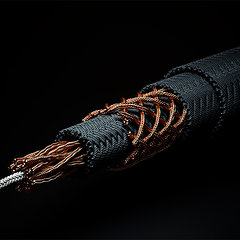

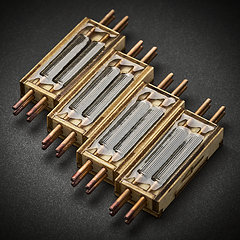

With emphasis on precision of craftsmanship, sleek, contemporary, design, and last but not least, the importance of Panzerholz on the end resulting sound achieved by using the Firewall, I am happy that when art meets science, and the teams involved is as adamant about their art as we are at ours, a truly strong product with innovative technologies is born, and we can take a new step towards higher fidelity sound. Sneak peek at the new LessLoss Tunnelbridge interconnect solution We are also hard at work creating the final design of the LessLoss Tunnelbridge distortionless interconnect system. Here is a picture of the prototype faceplates, both front and back. The laser engraving is another special feature which we are happy to offer as something that will simply ‘last forever’ and never wear out.

Thank you for your interest and continued patience while we work hard to provide you with our highest quality performance. I will send more information as it becomes available! Have a nice day! Louis Motek ---- LessLoss Audio www.LessLoss.com |

- Products

- Power Cables

-

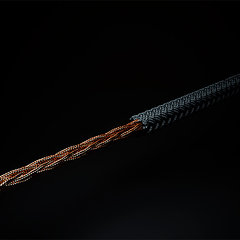

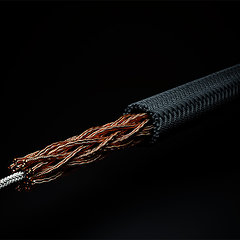

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

- Loudspeaker Cables

- Interconnect Cables

-

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

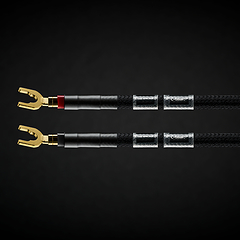

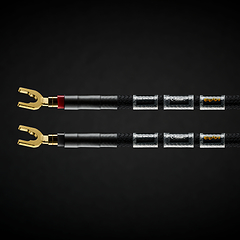

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-