BlackGround 10x Power Base production updateSaturday 31 December, 2022

Dear esteemed clients, The calendar moves on so ruthlessly! We are moving things as quickly as possible given all the holidays. It seems everyone in the city is getting colds, soar throats, all sorts of viruses. But we'll get through it. Laser engraver just got over his fever and is back in action.

They presented the work done only on sample pieces for now, to ensure the results will be as expected. They will do two lacquer coats minimum with a possible third or even fourth, with of course ample drying time in between. They quoted 4 hours drying time minimum between coats. So that means only two a day can be done. The work they presented me with was only one coat of lacquer on top of the color impregnation. They wanted to confirm the color. Here are some pictures. Looks nice so far!

But I did tell them to please carry it out with priority. Thankfully I didn't get one of those "who do you think you are" looks, so I think it's ok. I talked not only to the head of production, but also directly to the two fine ladies who were going to do all the preparatory work up until actual lacquering. Together we negotiated down from mink coats to chocolate. I'm an ok businessman, I think. Gotta find that right balance!

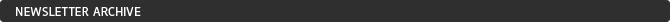

There is one "problem" that arose. One of the gentleman who does critical core work on the functioning BlackGround modules themselves fell ill with fever. But he has since overcome it as well. We have 50 units ready but that's only enough for 5 finished 10x Power Base units. He said another 50 would be ready by end of this week. This thing has been popular even only as a pre-order item already, so we have serious work to do. All ramp-up procedures are in place. Reacting quickly to demand, we took steps to accelerate certain production steps for the modules themselves. Especially to note are more high tech CNC 3D laser cutting procedures instead of semi-automated mechanical sawing as well as fully automated CNC lathing and threading work instead of hand lathing and semi-hand threading the contact posts. Polishing thereof is still a task done by hand, as well as ultrasonic vibratory bath and final high pressure steam spray and inspection, so that part can't be accelerated. But we are taking all the steps we can and I am happy to see the production time of the modules already pretty much halved. We'll all do the best we can to keep the lead time as short as possible and everyone is in good spirits. Especially because they know how eager you guys were what with the orders coming in in a steady flow up until now! Also, we have already ordered yet more wood for more enclosures because this entire first run is already sold out, and part of the second run is, too. The valiant guys at the wood milling shop were at it from 7am to midnight for that first run, because they knew if we don't get it finished we have to wait again for January the 6th! Which is our next scheduled day there again, so we'll do our next batch of milling on that date. The guys actually didn't finish at midnight, pooped out and not wanting to risk any mistakes, and came back in at 7am the next morning to do a final step which took another 2 hours. One thinks 'CNC' and would simply think 'fast action,' but when you look at the, what is it, 3m x 5m table, and that gigantic arm walking all around it, doing all kinds of intricate dance steps, you get to see reality in the face and the operations are so many and actually quite slow so as not to overheat the wood and tooling. Not quite a hot dog factory here but more of a high end sausage operation mixed with fresh greens from a garden that still uses soil. I'm so proud of all these guys putting this thing together. By the time you get it there must have been some 28 human hands caressing or tooling this thing from all angles inside and out. Then there'll be the final job of assembly which itself still requires three days for the epoxy to harden. We've already made a box full of the needed Jumpers for interconnection within. Epoxy has also arrived in bulk. The polished brass trumpet-shaped terminals are being finished as I write this. People, you have expressed great trust in LessLoss and we definitely won't disappoint! Thank you for your patience and support! And any day now, the first review will be published, which, I'm told, is going to be a real treat! I'll keep you informed, of course. A short reminder that you can still get a 394 USD discount and a free C-MARC™ Prime power cable to go with it (that's all you need for this unit) if you pre-order using our code. Head over to here and find out more!

Regards, Louis Motek | LessLoss.com |

- Products

- Power Cables

-

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

- Loudspeaker Cables

- Interconnect Cables

-

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs / Tax

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-

Beware of Fakes

Beware of Fakes