C-MARC™ Entropic Process RCA audio signal and digital cables now available!Friday 12 November, 2021

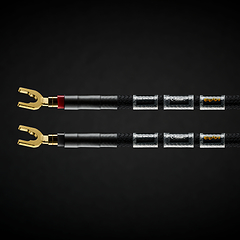

Dear esteemed Customers, We are happy to announce the availability to purchase our new state-of-the-art C-MARC™ Entropic Process RCA interconnects. These can be used for audio signals and for digital signals. The ordering page for the RCA audio cable is here. The ordering page for the RCA digital cable is here. These new Entropic Process RCA cables are made up of four key technologies, all of which add up to provide unparalleled signal transfer performance. These are: (#1) C-MARC™ conductor geometry. In particular:

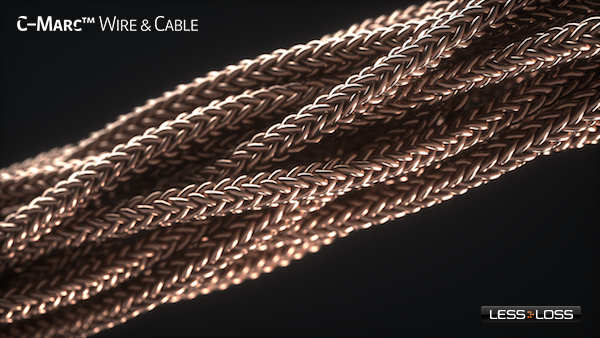

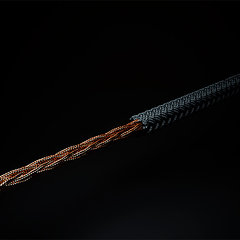

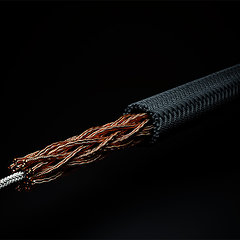

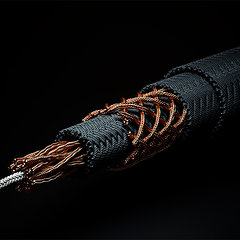

In the picture above you see how the wires are laid out. Important to note is that each of the small individual wires you see above are individually enameled. This means there's no electrical connection between each strand except at the very ends of the cable where the terminations are made. As a result, in each of the small braided bundles we see above, we're looking at two counter-polarized, elongated spirals. In aggregate these two counter-polarized spirals are both axially balanced (meaning that for every right turn there is also an associated and equally conductive left turn). Also, this means that over any given distance, the two counter-polarized coils are as close to being physically superposed as possible (diameter of one strand is a mere 0.125mm which means they are really hair thin). Why is this important? It is important and influential to performance because any wire acts as an antenna, inducing into it electro-magnetic waves from the surrounding aether. Since they are so close to one another, and counter-coiled in a balanced fashion, the induced noise is then canceled at the ends of the cable when both right and left coiled conductor carried interference achieve electrical addition, thus cancelling each other out. This same principle has been used in so-called hum-bucking guitar pickups since the 1930's. Here we apply it to the entire length of a cable. No only that, but we then replicate the process by again symmetrically laying out left and right balanced spirals of the already balanced micro-wires, resulting in a dual fractal replication of the geometry. The result is a very quiet noise floor upon which signals don't interact. The purity of tone thus preserved is something to marvel at. We use the same very labor intensive build process for both the center core and for the negative return "shield," resulting in the same benefits for both send and return lines. Below you can see how it all looks in cross section.

We investigated the mysterious burn-in phenomena over 20 years, following it very closely, and learning ever more about it, until we figured out a way to actually use it in design of actual product. This has been on our creative minds ever since day one when we first experienced it decades ago. But it remained elusive to us, until now! This does not mean we have abolished all initial changes in sound quality. It only means we developed means and methods to accelerate it, pre-prime it, so to speak, to the point where in your first two weeks of listening you might go through, say, some 200 years of regular burn-in. The burn-in process has not been downtrodden by us, but put on steroids to serve us even better! This is the benefit of the new Entropic Process. It takes us a substantially larger number of labor hours to make the Entropic Process version. One listen and you will immediately know that the effort is well worth it. Naturally this also demands patience as there is no way we can rush this sensitive and highly controlled manufacturing process.

Take any existing plastic covered cable and remove the plastic. You will be wowed by the sonic results. The sound is freed, becomes more natural, transients do not get colored by the 'sticky' slowness that plastics introduce, and so complex musical passages flow with ease and clarity as they should. In an effort to maximize natural tonality and to preserve sonic purity, all our signal and speaker cables are 100% cotton covered, which does not exhibit these flaws.

Hardwoods are much better at mitigating small vibrations than resonant metals such as aluminum. We have an entire web page dedicated to showcasing the striking differences in terms of ring time and speed of dampening. Take a look! Listen to the examples! This was all carried out in a controlled professional recording studio atmosphere and everything is calibrated so it is really a 1:1 comparison with no tweaking or fiddling with the results to enhance our findings.

Those who would like to upgrade existing LessLoss RCA signal cables to the new Entropic Process featured here will be happy to learn that we'll be publishing this opportunity in the near days to come. We are busy manufacturing these but again we must stress to all that the labor intensive nature of this superb product simply cannot be rushed. It is definitely one of our most labor intensive products overall. So please be aware of this. Thank you all for your support of our art. It is greatly appreciated and truly helps many engage in the fine art of music appreciation. With your help, we keep pricing within real-world confines, thus benefitting the maximum possible number of audiophiles. Which, by the way, reminds me of this: The LessLoss "global village" of customers Have you seen this lately? It shows how good ideas spread organically. Regards, Louis Motek | LessLoss.com |

- Products

- Power Cables

-

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

- Loudspeaker Cables

- Interconnect Cables

-

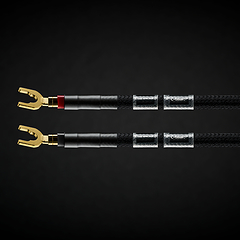

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

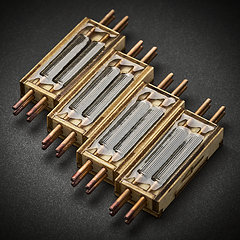

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs / Tax

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-

Beware of Fakes

Beware of Fakes