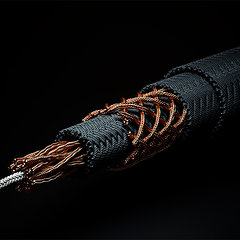

C-MARC™ Entropic Process RCA interconnect production progressMonday 11 October, 2021

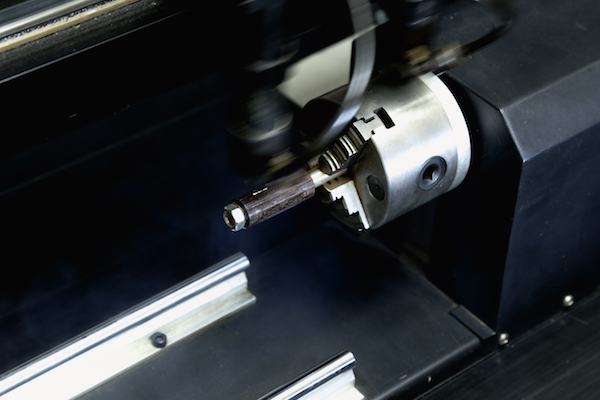

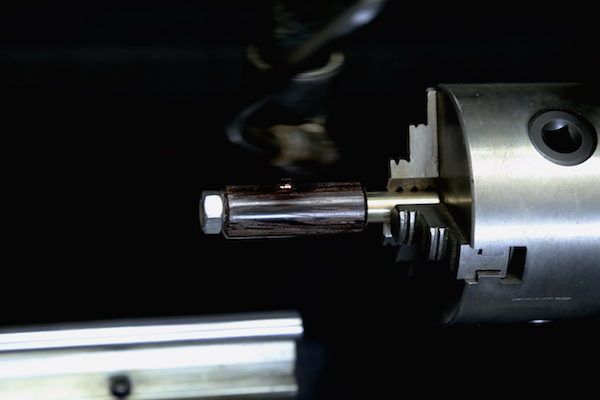

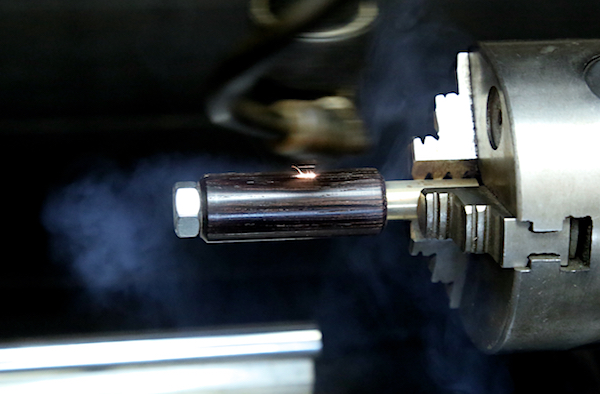

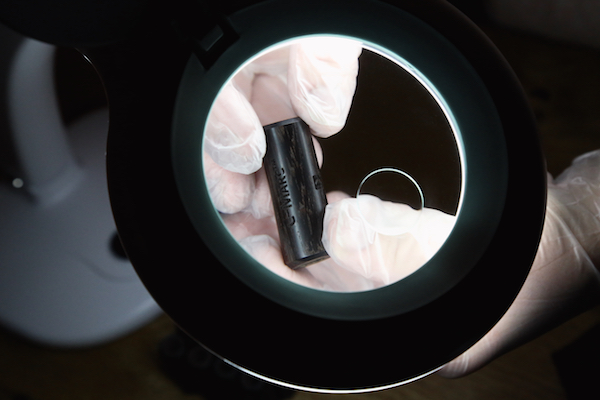

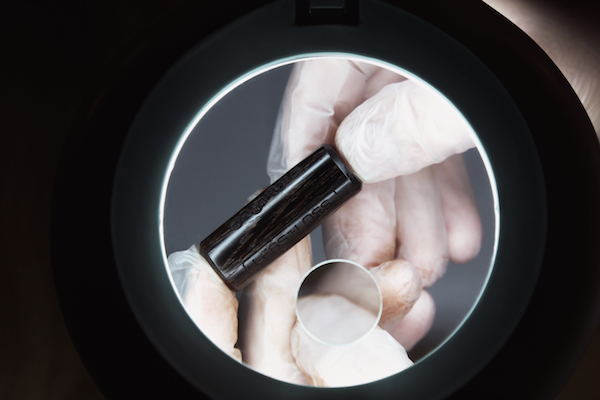

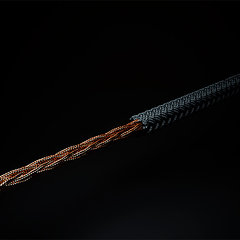

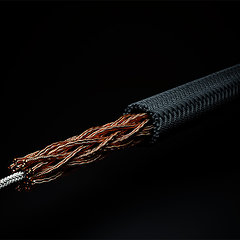

Dear esteemed Customers, Soon we will be releasing pricing and upgrade offers for the new C-MARC™ Entropic Process RCA interconnect cable. We are making good headway in pre-production, ensuring that we will be well in stock of all needed parts come order fulfillment time. What else can you expect from LessLoss other than meticulous attention to detail? To show you how much pride and dedication we invest in every detail of production, I'd like to share some more images from production. After the Wenge hardwood has been cut, drilled, lathed, pre-sanded, fine-sanded, and polished by hand, these then go on to be laser engraved. One by one, the chucks are inserted over a metallic rod and then bolted down finger tight.

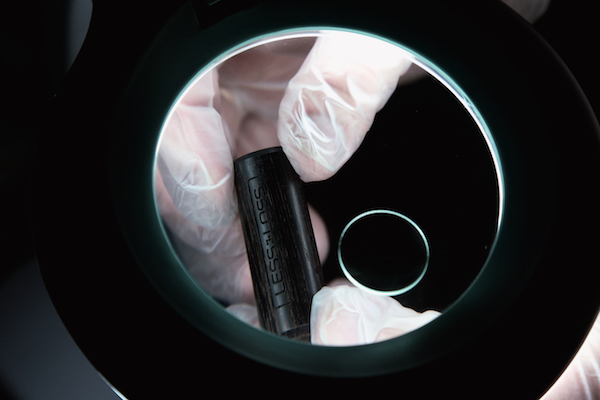

Each chuck, on both ends of the cable, will have this arrow engraved onto it (see following image). The cable must be so installed that the arrows all point from the source device, through the cable itself, towards the destination device. It cannot be emphasized enough how important this is. The entire core tenet of the Entropic Process relies on knowledge of the final cable's direction of signal propagation. If unheeded by the user, much painstaking effort we placed in all parts of this complex process will go to waste. Damage as such is not done to the cable in case the user sends signal down it in the improper direction. But the sonic richness will not develop according to plan, and sound stage depth will be lacking. If this cable is used in the improper direction, when corrected, it will take approximately 3-4 times the amount of time the signal passed improperly for the cable to even approach the initial state it was in prior to initial incorrect use. Further burn-in shall occur thereafter and eventually good results will be achieved. But it is important to heed proper direction upon first installation in order to reap the very best possible outcome from our design. There is so much technology packed into that little arrow, it will be well worth your effort to double and triple check it before reclining for that very special experience.

These processes continue all the way up to the very end of production of this cable. It takes well more than 3x the time to make a single stereo pair of RCA Entropic Process interconnects than it does to make the regular C-MARC™ version, which even by itself is already a great achievement in the realm of competing audio cable technologies.

After all has been inspected with a keen eye for any irregularities, the final hand polishing takes place, removing any residual fine soot from the laser engraving process.

Regards, Louis Motek | LessLoss.com |

- Products

- Power Cables

-

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

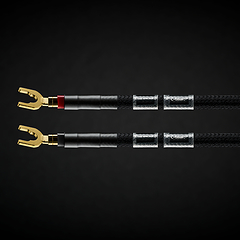

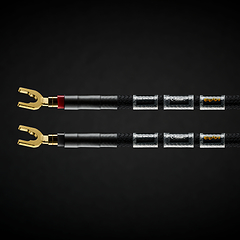

- Loudspeaker Cables

- Interconnect Cables

-

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs / Tax

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-

Beware of Fakes

Beware of Fakes