C-MARC™ production in full swing!Wednesday 26 April, 2017

Dear esteemed Customers,

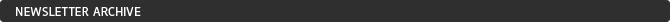

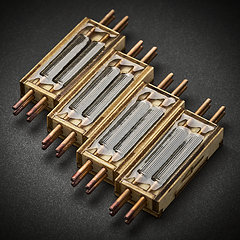

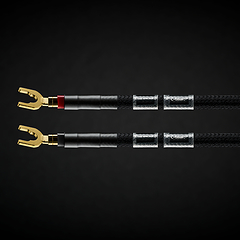

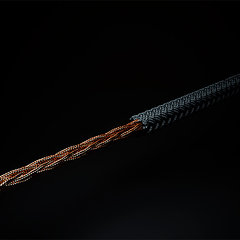

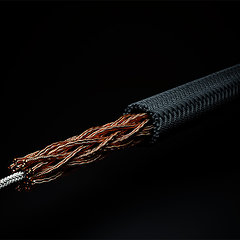

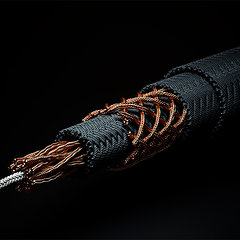

Many thanks to all of you who took the opportunity to pre-order the new C-MARC™ wire and cable products. You have enabled us to bridge our entire production over to the new technology without missing a beat. I know you want to see the final product but we are so busy at this point that we don't even have the opportunity to provide our professional photographer with finished product they could shine their beautiful studio lights on. Everything is being prepared for shipment to pre-ordering customers at this point.  What's it like to work with C-MARC™ cable? C-MARC™ is not like ordinary cable, where you can tear off the plastic insulation in an instant with a wire stripper tool. With C-MARC™, you have to in a sense "create plastic" where you want stiffer protection. We carry this out by hand winding fine cotton thread and adding a few carefully placed drops of Cyanoacrylate glue. The cotton fibre self-amalgamates in reaction to the glue, forming something akin to an epoxy impregnated fibre laminate when it hardens. Thus, the prepared endings' contacts are cemented into place before we attach the connectors. It takes a skilled technician with a steady hand and a good hour or more of labor to prepare just a single ending. Not your most production friendly process, but one that is so hypnotically beautiful in resulting quality and maturity of tone, we are sure this is the winning formula for superb sound you'll want to stick with! We have to make hundreds of these cables and we carry this out in manageable batches such as the one below. C-MARC™ bulk wire has been ordered by several intending to implement them as an upgrade to their loudspeakers' existing internal wiring. In for a real treat! Those awaiting C-MARC™ RCA interconnects are in for a really big experience: the noise floor is pretty much on par with with well implemented XLR, without the associated added circuitry necessary to balance/de-balance the line. Solid copper, generously silver plated, heavy and very well made Xhadow RCA connectors are used in the C-MARC™ RCA interconnects. The art of end preparation and electrical attachment is scrupulously supervised to ensure that maximum benefit is won through C-MARC™'s innovative auto-reduction of noise.  Shipping schedule, or: "So, how much longer do I have to wait?" We began last week and have ramped up production this week. Some items are already prepared for shipment. Many orders are near completion at this point. The back log of pre-orders is pretty long, but we are beginning to glean our production tempo working with these new materials. Deliveries start in just a couple of days as we work down the roster. It may be that all pre-orders will have been shipped within 14-21 days! Labor intensive production is putting it mildly. There are some 64 meters of C-MARC™ core braid per meter of Triax cable. By "core braid" I mean that the first braiding step is about 0.7mm of D=0.125mm wire! That is a LOT of intertwined, counter-polarized windings in a single meter of cable. Like never before. Thank you all for your patience and support of this great new generation product! I know you will be most pleased with the sonic virtues which lay ahead. We take great pride in manufacturing each and every cable for each and every one of you. Thanks! Regards, Louis Motek | LessLoss.com

|

- Products

- Power Cables

-

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

- Loudspeaker Cables

- Interconnect Cables

-

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs / Tax

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-

Beware of Fakes

Beware of Fakes