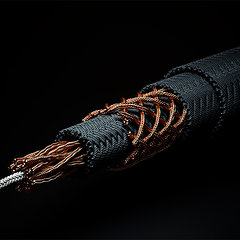

The DFPCs (Dynamic Filtering Power Cables) are much more than mere power cords: each model employs a different grade of LessLoss Skin-filtering, representing not only substantial leaps in performance, but the most elegant and effective power filtering technology ever manifested in a power cord. Today, with more electromagnetic (EM) pollution on more bandwidths than ever before, EM noise easily infiltrates your components through the power line. Once inside, it causes widespread distortion, significantly degrading many aspects of music playback. Our Skin-filtering technology prevents this undesirable noise from entering your equipment—without impeding dynamics (unlike traditional power filters). The result is an all around enhanced performance. With each grade of Skin-filtering, our DFPCs provide progressively clearer insight into your signal’s character, guaranteeing an audibly more faithful presentation of the music.

Recordings using the DFPC (MP3 previews):

|

|

|

|

|

|

| Grand Piano |

Solo Flute |

Chamber Music |

Percussion Duo |

Grand Piano |

Choose and purchase your cables here.

Most are now available and ready to be delivered.

For special requests or for additional information, please write to Louis Motek: [email protected].

|

|

|

Plug Option: USA

This is the Oyaide model P-079, which is made according to the NEMA 5-15 (North American 15 A/125 V grounded) standard.

|

|

|

|

Plug Option: Schuko

This is the Oyaide model P-079e, which is made according to the CEE 7/4 (German "Schuko" 16 A/250 V earthed) standard.

Phase

In the LessLoss power cables featuring the Schuko plug option, the power's "phase," or "Live," connection should enter the plug into the leg marked "DVE" and not into the leg marked "CE" on the black plastic of the Oyaide plug. Thus, the Live signal comes out of the hole marked "L" on the IEC connector. All LessLoss power cables are wired in this way.

UK / Australian

UK / Australian Plugs

UK or Australian type plugs are available as a custom option. We normally use power plugs from Oyaide in Japan, and they do not offer UK / Australian type products. Furutech makes UK and Australian type wall plugs which we can use instead. We have done this several times with excellent results, and it does not compromise our product's performance, looks, or safety. A minimal surcharge and lead time will be applicable. Please write to Louis Motek for more information on [email protected].

|

|

|

|

|

|

|

|

Price: $595 (legacy item - please inquire)

2 cables – 5 % off

3+ cables – 10 % off

|

|

|

|

Plug Option: USA

This is the Oyaide model P-079, which is made according to the NEMA 5-15 (North American 15 A/125 V grounded) standard.

|

|

|

|

Plug Option: Schuko

This is the Oyaide model P-079e, which is made according to the CEE 7/4 (German "Schuko" 16 A/250 V earthed) standard.

Phase

In the LessLoss power cables featuring the Schuko plug option, the power's "phase," or "Live," connection should enter the plug into the leg marked "DVE" and not into the leg marked "CE" on the black plastic of the Oyaide plug. Thus, the Live signal comes out of the hole marked "L" on the IEC connector. All LessLoss power cables are wired in this way.

UK / Australian

UK / Australian Plugs

UK or Australian type plugs are available as a custom option. We normally use power plugs from Oyaide in Japan, and they do not offer UK / Australian type products. Furutech makes UK and Australian type wall plugs which we can use instead. We have done this several times with excellent results, and it does not compromise our product's performance, looks, or safety. A minimal surcharge and lead time will be applicable. Please write to Louis Motek for more information on [email protected].

|

|

|

|

|

|

|

|

Price: $1149 (legacy item - please inquire)

2 cables – 5 % off

3+ cables – 10 % off

|

|

|

|

Plug Option: USA

This is the Oyaide model P-079, which is made according to the NEMA 5-15 (North American 15 A/125 V grounded) standard.

|

|

|

|

Plug Option: Schuko

This is the Oyaide model P-079e, which is made according to the CEE 7/4 (German "Schuko" 16 A/250 V earthed) standard.

Phase

In the LessLoss power cables featuring the Schuko plug option, the power's "phase," or "Live," connection should enter the plug into the leg marked "DVE" and not into the leg marked "CE" on the black plastic of the Oyaide plug. Thus, the Live signal comes out of the hole marked "L" on the IEC connector. All LessLoss power cables are wired in this way.

UK / Australian

UK / Australian Plugs

UK or Australian type plugs are available as a custom option. We normally use power plugs from Oyaide in Japan, and they do not offer UK / Australian type products. Furutech makes UK and Australian type wall plugs which we can use instead. We have done this several times with excellent results, and it does not compromise our product's performance, looks, or safety. A minimal surcharge and lead time will be applicable. Please write to Louis Motek for more information on [email protected].

|

|

|

|

|

|

|

|

Price: $1824 (legacy item - please inquire)

2 cables – 5 % off

3+ cables – 10 % off

|

Free Worldwide express shipping.

Most deliver in 2-3 business days.

Save ink and paper –

print from here!

The problem: an atmosphere full of high-frequency trouble

The world is saturated by high-frequency signals. In fact, vacant frequencies are no longer available. The growing tendency is to stuff more and more data into narrower and narrower frequency ranges:

As if the proliferation of wireless technologies and the omnipresent usage of mobile devices were not enough, consider this: the power grid’s own wires are used as communication lines, and even as internet broadcasting networks, while at the same time boiling your ritual morning tea. In the air, information carrying frequencies extend well into the multi-GHz range, bordering on infrared light frequencies. Through cell towers and satellites, everybody is connected to everyone at once: real time streaming of audio and video, live desktop sharing, global conference calls, and cloud computing—all of this is spreading like wildfire throughout the aether. There is no "EM-sanctum" for us audiophiles, and our private music playback quality suffers dearly for it.

Evasive influence of radio waves

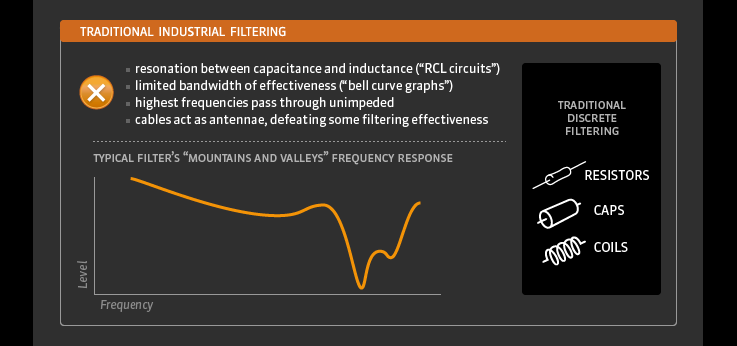

Your components are connected to power cords, and those power cords to power lines; these power lines (including your power cords) not only transfer power, but also act as antennas. Capacitive and inductive coupling (how an antenna receives a signal) allows any plethora of HF noise to enter your gear either (a) through the power lines, then into your gear through your power cords, or (b) directly into your power cords and into your gear. Once inside, an unpredictable cacophony of HF signal interaction occurs with every internal circuit. This is called

intermodulation distortion. Through this process of haphazard interaction, information is added to and taken away from the component’s internal signals. In this way, the audio signal’s integrity is lost.

The adverse effects of EM noise can be born in any powered gear, and then travel to the next piece of gear where the problem is compounded by more intermodulation. By the time the signal reaches the speaker coils and becomes sound, a sort of acoustic haze pollutes the audio event: spaciousness and dimensionality are diminished, instrument delineation is clouded, the noise floor is raised, and treble audio frequencies are artificially embossed. All of us have at one point or another mistaken much of this for sonic detail, with it later resulting in listener fatigue or confusion. It is therefore crucial that we audiophiles take our power quality seriously.

My audio components already have power filters, and my cables are well shielded, so what good are DFPCs?

An audio component’s internal power supply circuits are designed to filter only a partial region of the complete frequency spectrum. Higher frequencies are able to circumvent both capacitors and coiled chokes found in traditional power filters. Heavily shielded cables will also fail to achieve the results we strive for—even if run through a thick metal tubing: capacitance from shield to conductor, from shield to shield, and from wire to wire will pick up HF noise through capacitive and inductive coupling. The capacitance of an inductor, and the inductance of a capacitor will always be penetrated by higher frequencies than the traditional filter is designed to cut off. The influence of the huge remaining HF spectrum that our DFPCs filter has been seriously underrated and neglected.

So why don't you just publish your superior HF-attenuation data?

If only it were that straight forward. The problem is that the scope of measurable frequencies is smaller than the scope of influential frequencies. Since a power line has no characteristic impedance, it is impossible to authoritatively measure higher frequencies at all wavelengths and locations along the line. When measuring a signal whose wavelength is shorter than the signal path in question, one will inevitably encounter unpredictable nodes and peaks. A measurement at one location gives entirely different results at another. The data gathered simply wouldn’t be meaningful. That said, it would be absurd to abandon the idea that HF noise affects audio, simply because of measuring restraints.

Power lines run for hundreds of miles, so how could a six foot power cord make any difference?

The popular contention here is that if HF noise builds up along the power grid, all the way to the wall receptacle, then after hundreds of miles there would be so much HF noise that no audiophile power cord could filter it all out—not even a significant amount.

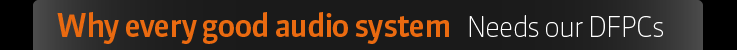

The main problem with this thinking is its failure to consider the confined way natural laws allow electricity to travel in a wire. Note this principle of attenuation:

The higher the frequency, the more rapidly it suffers attenuation along a wire.

This is an entirely natural phenomenon. In high frequency communication lines, re-amplifiers have to be placed at certain crucial distances, or the signal will diminish and loss of data will occur. The higher the frequency, the more of these stations are necessary. This is also why industrial manufacturers of HF communications cables are required to publish attenuation-over-length data—it is inherently difficult to keep HF signals from attenuating over long distances.

Because the less distance HF noise travels down a line, the less attenuation it undergoes, it follows that HF noise induction nearest the end of the power line introduces the highest HF noise at the highest intensity into your gear. Since HF noise (as seen by the gear) will be least attenuated when induced closest to the gear, it follows that the portion of the power line occupied by the power cord itself will have the greatest influence on the power quality provided to the gear.

The question, therefore, should not be about how HF noise in the last six feet could possibly influence the sound, but instead how HF noise in the first 99 miles could possibly influence the sound. For it doesn’t. It can’t. HF signal attenuation occurs long before the wires even reach your neighborhood. The power cord is the part of the power line that matters most.

Summary

High frequency signals, extending far into the multi-gigahertz range, permeate our atmosphere every day and many have not yet come to adequately appreciate the profound effect such noise has on the listening experience. Because it is indeed inconsequential to the audio gear’s lower realms of mere purpose-built functionality ("hey, it plays..."), HF noise is allowed to circumvent gear-internal filtering circuitry through capacitive and inductive coupling. Detrimental effects are widespread as HF noise causes distortion via haphazard intermodulation throughout the gear’s circuitry. Without proper filtering, significant signal degradation is inevitable. HF signals naturally attenuate along wires, making HF noise on the power line most intense the closer it is induced to your gear. So, any means employed to prevent HF noise from entering your gear will be most effective closest to the gear’s IEC inlet. The power cord therefore occupies the most critical location to condition power for higher quality audio purposes.

What we need now is a musically effective solution. We need an all-in-one power cord that transfers power, filters HF noise, all the while leaving dynamic performance and natural tonal balance intact.

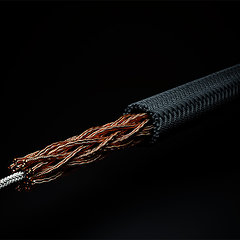

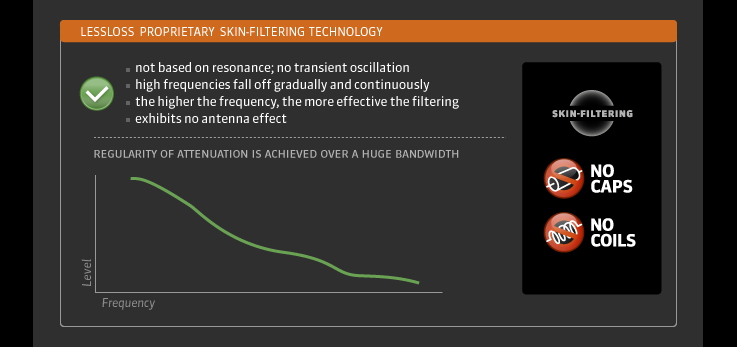

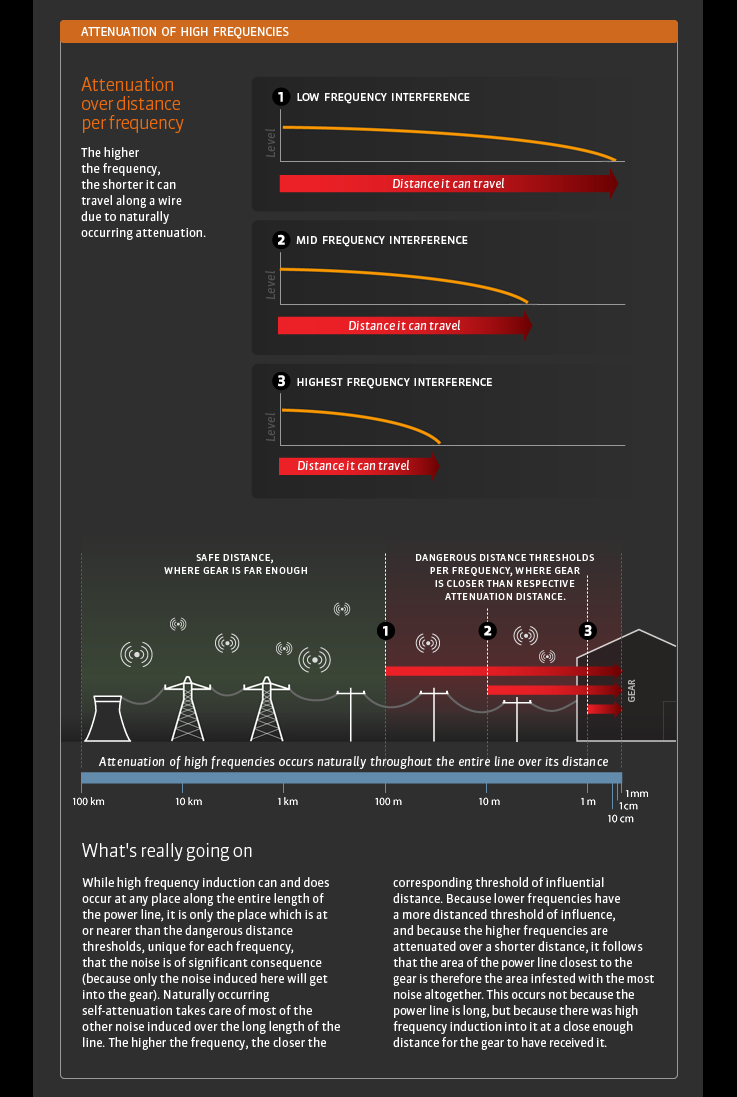

Skin-filtering is our solution to the problem of HF noise. It is a proprietary technology developed by LessLoss, fundamental to the effectiveness of the DFPC.

Users the world over attest to its efficacy and cost effectiveness. It makes perfect use of the laws governing the behavior of alternating electrical signals traveling down a wire. Its foundation is the principle of attenuation over distance, and of the high frequency skin effect first described mathematically in 1883.

Because nature determines that high frequencies reside at the skin of every conductor, it is easy to understand why LessLoss Skin-filtering is the audiophile's best and most efficient tool to condition the power before it enters his or her audio component. Treating the skin of the conductor attenuates HF noise, preventing it from entering your gear. Because this filtering solution is employed only at the skin of the conductor, the solution never restricts the low frequency power flow that your gear relies on. This way LessLoss Skin-filtering provides enhanced HF attenuation along the entire length of the cable, all the way to the IEC inlet. Unlike traditional filters and conditioners, it does so without compromising dynamics or coloring the sound.

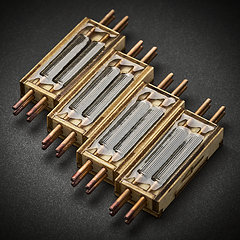

How it sounds was our driving concern while selecting the most suitable power plugs for the DFPC. We scrupulously tested more than 20 different candidates of power plugs (eg., Wattgate, Furutech, Oyaide, and others) from all over the world, carefully considering design aspects which contribute to the most organic, natural sound. Contrary to their pricing gradation, for us, the winner wasn’t any manufacturer’s top-of-the-line connector; the clear winner was the Oyaide ruby-colored 079 series.

Oyaide 079: high quality, high performance

The 079’s contact pins are individually machined out of single pieces of solid bar stock (deoxidized phosphorous bronze), instead of being stamped, crimped, or welded together, as is standard practice in mass manufacturing. This offers the best conductivity. Also, no nickel plating is used between the bronze and 24K gold. Instead, the surface is polished by hand, twice. These two polishing processes, combined with two layers of gold, yield a mirror perfect finish.

Hand polishing is carried out to a perfection which the audiophile will appreciate. Does this seem unnecessary? Nobody would go to this trouble if it weren’t audible, right? We tested it. A little fine sandpaper and a few cringes later, we must confirm Oyaide’s findings. For more information please see the manufacturer’s website:

www.Oyaide.com

The 079 is rigid, stable, and mechanically strong. It is heat-resistant up to 200°C. The shell of the connector is made of high density PBT with 30% glass-particle filler introduced into the body holding the electrical contacts. This provides high resonance absorption while maintaining excellent rigidity and stability when used with warm temperature gear (especially important under warmer operational conditions where power plugs lose rigidity and can consequently sound muddy).

Regarding the IEC connectors, it is the pressure of the contact surface area which defines much of the quality. Through experimentation, we found this to be as audible in the ground connection as it is in the two power connections (live and neutral).

Oyaide does not compromise on metal costs. The very generous thickness of metal used gives the IEC plugs a spring action so strong that even hundreds of connections in and out do not compromise their grip.

079 vs. 004 and M1/F1: power plug shootout

First, the differences: the 079 features two layers of gold plating over deoxidized phosphorous bronze contacts. The 004 and the M1/F1 connectors both have the same beryllium copper which is then plated with layers of platinum and palladium. One would expect the plugs with copper to be more conductive, but one must also consider comparing the gold plating to the combination of platinum/palladium, which represents the actual contact. In this case, gold is more conductive. So on paper, neither solution reveals itself as necessarily better. Listening tests are in order.

Sonically, the 004 is nearly identical to the the M1/F1 (platinum/palladium). The only physical difference between the 004 and the M1/F1 is the differing structure and materials of the outer barrels which enclose them; everything else between them is identical. It is therefore clear that their small difference in sound is due to the differences in their barrels.

Now, comparing the 004 (platinum/palladium) against the 079 (gold), the sound is substantially, even unmistakably different, yet their barrels—apart from color—are identical (PBT). Thus, we now know definitively that the primary factor affecting sonic performance is not the shell, but rather the difference between conductive metals and their platings. And, as noted, the 079 (gold) had the more conductive surface metal. But what about the differing core conductive materials? This called for further listening tests.

We conducted our listening tests on many very different audiophile systems, and in many countries. These systems range across nearly the entirety of audiophile culture: from full-range electrostatic loudspeakers, to one-driver Lowther horn systems; from the most exotic CD transports, to high end computer audio playing from RAM on battery power; from hand made ribbon tweeters, to highly efficient horns; from transistor amps, to single-ended tube solutions; from large dedicated rooms, to small rooms and headphones. After conducting our listening tests across these systems, we must conclude that the 079 outperforms both the 004 and the M1/F1. Even putting the 079 metal contacts into the M1/F1 barrel did not result in a more neutral sound, but developed an element of artificial flavor. Further attempts to ground the aluminum barrel, though helpful, only led to unsatisfactory results.

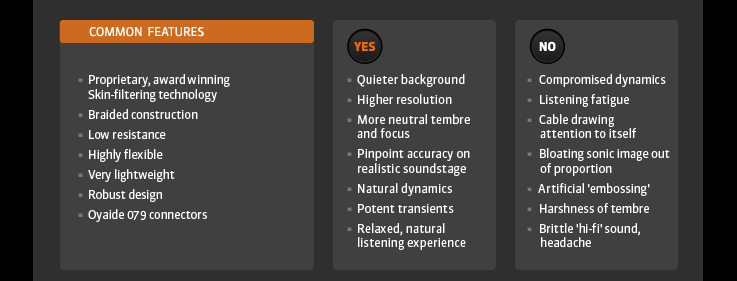

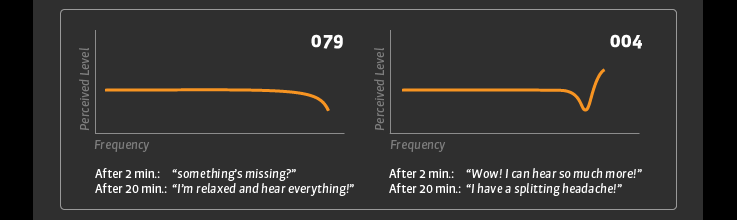

Sonic differences between 079 (gold) and 004/M1/F1 (platinum/palladium)

After listening for only 2 minutes, most any audiophile will at first greatly prefer the 004 to the 079. A brilliant and sweetly extended high frequency sound is immediately appealing and seems at first to reveal more nuance. Bass seems very robust too, but all of this turns out to be an illusion by manipulation of harmonic content. It turns out to be a "hi-fi" effect that does not satisfy over time.

The following is a "poetic" way to describe the subjective sound imparted by the two different plugs. It is not a measured quantitative finding, but a clear depiction of the subjective resulting sound difference between the two. In reality we’re dealing with different fine shades of distortion which are truly beyond measurable quantities. So it is for the sake of simplicity, to offer you a feel for what we’ve gathered through our experience, that we present this drawing.

What we’re trying to express here is that overall, the 079 gives the subjective impression of being the more natural of the two. There is nothing artificial for the ear to "hold on to" or to perceive directly as a constant element. The gold-plated 079 seems to emulate the natural function of the ear more closely, and so it sounds more natural and genuine to the listener over time. Any slight roll-off effect one might initially suspect to perceive turns out to have been an illusion produced by comparing to the harsher, etched, unnaturally embossed high-frequency sound of the 004. This isn’t to be confused with any failure to reveal high frequency content; we’re speaking only of the content’s color.

The 004 initially creates a more 'sparkling' impression; however, approaching 20 or 30 minutes into the listening session, we realize more and more the true sonic signature of this plug. A persistent element in the sound begins to grow on you, then to disrupt the listening experience. This is made even more plain when there are 4-6 such cables powering the system. There seems to be a sort of "dip" followed by an unnatural excitation of the topmost harmonics. This beautifully (perhaps overly) detailed sound then quickly becomes tiring and fatiguing to the ear. Over the long run, it is definitely not as natural to the ear as the 079. And it is exactly the long run that we audiophiles are most interested in. Over the long run, if a solution makes it impossible to enjoy music in a natural relaxed state of compelling listening, it isn’t desirable even if the initial impression was one of more detail. The sonic detail revealed by any component should be tolerable over the long run in order that it thus prove itself to have been natural all along.

Had these comparisons been carried out on only one or few systems, there may have been a plausible explanation elsewhere, such as in some other system fault which was simply being revealed by the 004; however, we emphasize that some 20 radically different systems were used to gather this experience. These tests were carried out on systems ranging from Panasonic boom boxes all the way up to systems costing over half a million Euros. We were scrupulous in our analysis. Over 25 talented listeners took part, among which were audio professionals, musicians, life-long audiophiles, and equipment designers passionate in their art. We certainly did not rush to this conclusion.

Given the functional superiority of our Skin-filtering technology, we sought only the most natural sounding, and not necessarily the most expensive, connector to accompany it. We’re sure you’ll be happy with our choice of the Oyaide 079. It provides a natural depiction of the recorded material. Enjoyment over time is more important than hearing a few minutes of exaggerated detail. Who wants that, only to suffer a headache the rest of the time and have his or her attention drawn to the connector rather than the music? With the 079, you can sit down for a pleasant evening of listening and focus on the music, liberated from all these electronic compatibility issues.

Below is a guide for choosing the right DFPC(s). We assembled this to help you make your best-informed decision in areas of cost and performance.

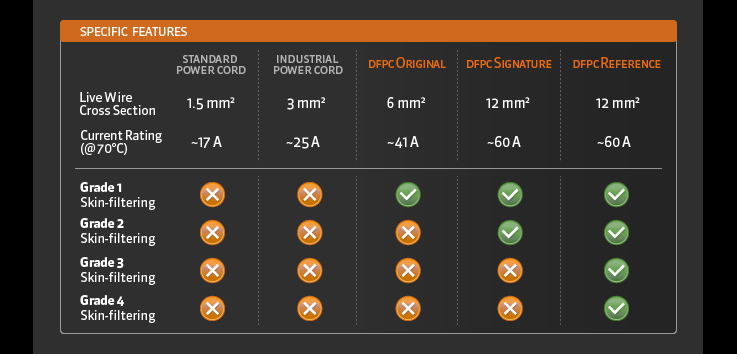

Differences between the DFPC Original, Signature and Reference

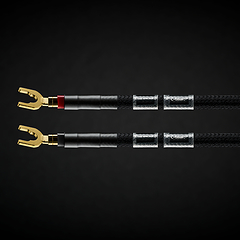

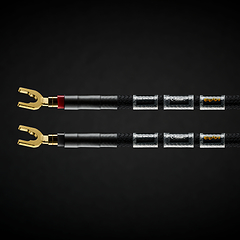

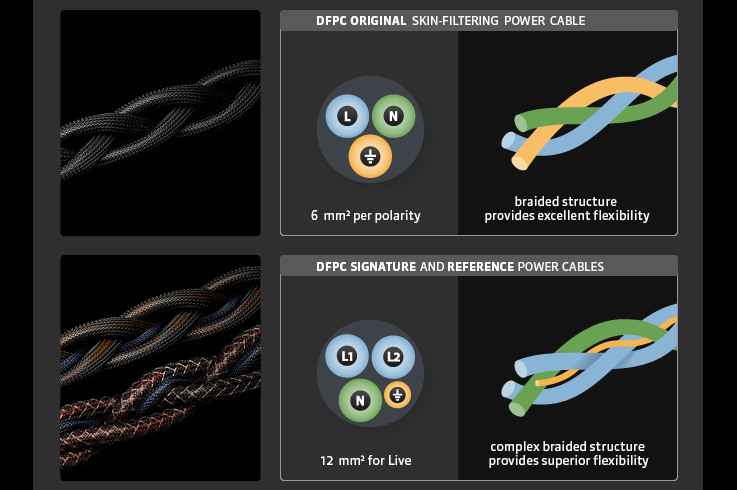

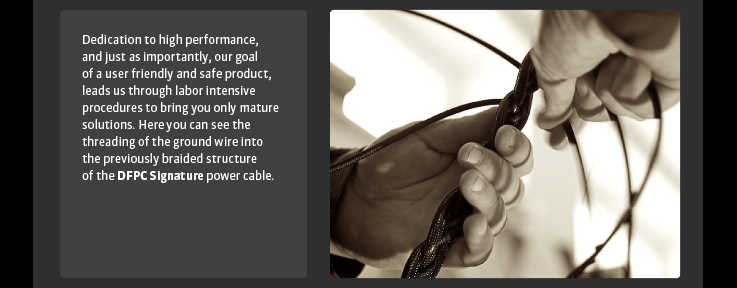

Physically, there are two main differences between the DFPC Original and DFPC Signature/Reference models. One is the difference in cross section of conductive material. The other is the differing grades of our proprietary Skin-filtering technology. Beyond these two differences, the Signature and Reference are more difficult to produce than the Original and require substantially more time. All DFPC series power cables are assembled by hand, not cut from mass-produced spools.

Live wire cross section

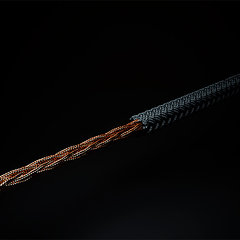

The DFPC Original features a 6mm2 live wire. This offers excellent dynamic performance even for power hungry amplifiers. Yet through its braided design, the DFPC Original remains very flexible, aesthetically appealing, and is easy to use.

The DFPC Signature and Reference have double the conductive cross section of the DFPC Original on the live line. While the DFPC Original has three inter-braided conductors (one each for live, neutral, and ground), the DFPC Signature and Reference have four (two for the live connection, one for neutral, and an additional for ground). Doubling the cross sectional area for the live line achieves more natural clarity; immediate control of lower bass frequencies; and middle frequencies become more liquid, smooth and clear.

This enhancement has merit because in the process of delivering superior sonic performance, it solves all of these seemingly irreconcilable problems. (1) Flexibility: enlarging the Original’s 6mm2 cross section poses a serious problem for cable flexibility. The cables could become unwieldy, stiff and precarious to use, whereas the DFPC Signature and Reference are not. (2) Harsh sound: solving the first problem usually requires multi-stranded wire, which leads inevitably to a harsh sound. The DFPC Signature and Reference do not. (3) Compromised microvibration control: a stiff cable can make component microvibration control difficult, as sensitive footers often rely on balance and finely tuned weight distribution. The DFPC Signature and Reference are flexible. (4) Fit, safety and aesthetics: heavy gauge wires would no longer fit into the Oyaide plugs, and this could seriously compromise operational safety, not to mention impinge on aesthetics. The DFPC Signature and Reference are elegant and at the same time safe to use, even if accidentally stood upon.

Even though the DFPC Signature and Reference double the cross sectional area of the Original’s live line, they still solve all these problems while delivering a substantially higher level of performance. Also, with their augmented cross section, and their higher grades of Skin-filtering, the DFPC Signature and Reference weigh only some 50 grams more than the DFPC Original and are every bit as robust, reliable, and flexible.

Skin-filtering grades

Each LessLoss Skin-filtering grade marks audibly significant improvements in performance. The DFPC Original uses Grade 1. With just this technology, many customers insist that their stand-alone "caps & coils" power filters are no longer needed, and often that comparing with a DFPC reveals that their previous filter imparts an undesirable flavor to the sound. Grade 1 Skin-filtering makes a substantial step beyond the performance of standard or industrial power cords; indeed, a substantial step even over power cords with much higher price tags.

The DFPC Signature’s Grade 2 Skin-filtering requires a more extensive processing of the conductor’s outer skin. It involves a unique utilization of pigments in a specialized in-house prepreg process. This achieves more attenuation of wide-bandwidth HF noise and results in an even cleaner sound as the true nature of the signal is better revealed above an even lower noise floor.

For three years we have been refining Skin-filtering Grades 3 and 4, found only in the new DFPC Reference. Here, we not only implement all steps involved in the production of the DFPC Signature, but, in addition, carry out several more crucial steps in the processing and assembly of each cable. This level of attention to detail and performance places this cable in an entirely different category. Each DFPC Reference undergoes half a month of controlled steps in production. Assembly alone takes 12 hours of scrupulous labor. There is much more than meets the eye in this product, with performance to match.

Careful pre-conditioning processes

All DFPCs undergo our house-developed proprietary seven day uninterrupted post-processing procedures, which provide the foundation upon which the cable will then later burn in when in use. This includes determining an electrical directionality for the virgin metal used in manufacturing, as well as other proprietary details of qualitative influence. We take pride in our products and never ship anything which is not the very best we can accomplish in terms of quality, reliability and performance. When you buy a DFPC, you’re purchasing a hand tailored product born from years of research and building experience, with an exacting attention to detail in all we know to influence sound quality.

Which component do I use a DFPC with first? Does it matter?

For the most cost effective performance according to budget, follow these rules:

(1) If you’re using exclusively DFPC Originals, DFPC Signatures or the DFPC Reference, apply them to your system’s components in the following order.

(2) If you’re using at least one DFPC Signature, and the rest are DFPC Originals, or at least one DFPC Reference, and the rest Signatures or Originals, first apply the Reference or Signature(s) in the following order, and then apply the DFPC Original(s) to the remaining components.

1st: Source (CD player; DAC; phono preamplifier)

2nd: Power Amps

3rd: Preamplifier

4th: Power conditioner; regenerators, power distribution units

5th: Phono motor

Reasoning

Source first. The most crucial function of any audio system is the correct formation of the audio signal. Starting with the source allows for a better formed original signal, and allows for a more accurate performance assessment of everything happening to that signal "downstream." This is because the signal can only degrade in quality as it goes from component to component, always in various ways experiencing loss along the way to the speakers. If, due to the source component’s impure power, the original signal is distorted from the outset, then no amount of component changes, tweaks, or power filtration attempts "downstream" will alleviate the problem.

Amps second. An amp’s function is invasive, using power from the mains to actively raise the power of the signal through amplification. In this respect, the power’s quality has direct influence over the quality of the signal.

Preamps third. Preamps lower the audio signal level, often passively through variable resistors or transformers. Their power often controls only LEDs, displays, and input/output switches. Therefore, their power’s influence is sometimes more removed from direct invasive influence on the signal’s quality; although, this depends on the specific preamp in question.

Power conditioners, regenerators, or power distribution units: fourth. These units are fourth because, as they’re always removed from your components by some distance, their position is less than ideal to filter HF noise. There are two things to consider, however: first, one DFPC feeding all components through a power distribution unit allows the Skin-filtering there to work for all components together. The downside, is that it leaves more "antenna" between the distributor unit and the components themselves—the place which, if not filtered directly, is the most vulnerable to the strongest HF noise pollution. Therefore, if you’re going to use a DFPC before the power distributor, make sure the components themselves already use DFPC Skin-filtering cables. This will then have the added benefit of enhancing all the rest of your DFPCs by in effect lengthening all of the other DFPC Skin-filtering cables by the length of that first wall-to-distributor cable.

Note: Please consider how you use so-called power regenerators and DFPCs together. Always compare the results of using any combination of regenerator and filter, against a DFPC going from the wall, directly to your component. Many of our customers are reporting that a DFPC going to a completely passive power distributor (e.g., 6-outlet Furutech e-TP609 or e-TP60), then on through DFPCs to the rest of the system, outperforms regenerators, filters, and combinations thereof.

Phono motor, fifth. Here, the sound quality improvements can be surprisingly large, and it has nothing to do with vibrations of the physical platter; rather, it has to do with the cartridge having a coil to produce the signal. The coil picks up EM radiation from the motor coils. The proximity is close enough such that changing from a stock power cord to a DFPC radically enhances cartridge performance. Not everything is mechanical in turntables. A lot still has to do with EM interactions, especially when the signals generated by the needle and coil are so minuscule and amplified millions of times before they exit the speaker. The proportion of noise, then, picked up by the coil in the cartridge, is crucial to the quality of the resulting sound we hear, since it too will be amplified millions of times.

Why is this point last (It is, after all, by the source)? It is last because this induction is very low-level, and will be most appreciable when other more obvious sources of noise are dealt with first (following steps 1-4 above).

After having sent out well over 3000 Skin-filtering power cables and having received a significant amount of feedback from users the world over, there is substantial agreement between our customers’ experience and the above general reasoning.

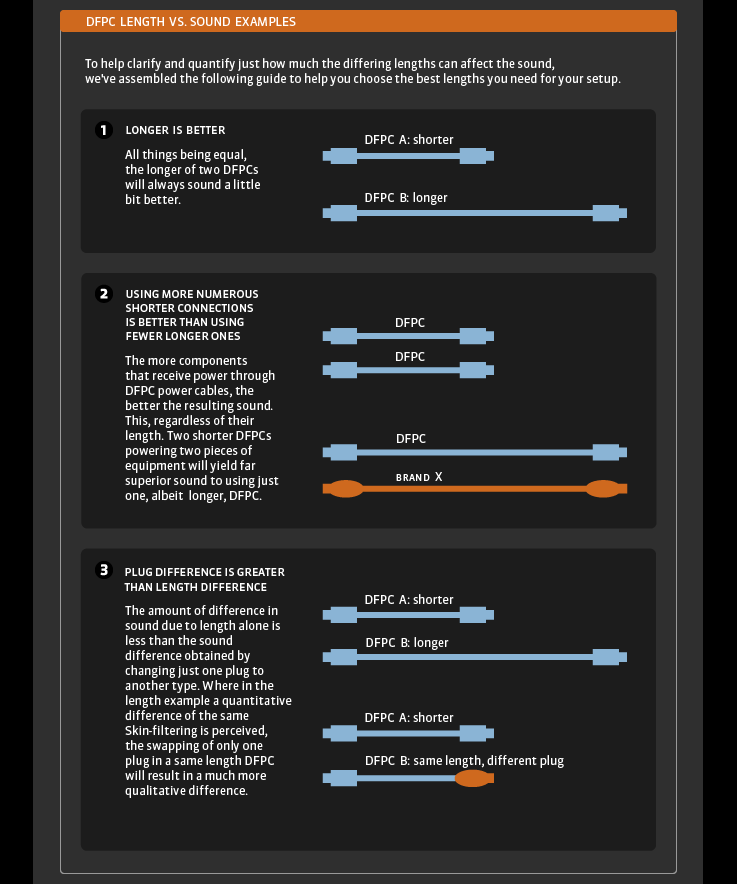

Choosing the best length

DFPCs are available in lengths ranging from 1-3m. Longer lengths sound somewhat better than shorter lengths, but the degree of difference is marginal. (Just for context, using any other type of plug on a DFPC makes a much more substantial difference in sound quality). If it is for sound quality alone, don’t burden yourself with needless length—it isn’t worth it. Instead, purchase the lengths which best fit your system. The LessLoss DFPC is very flexible and poses no problems upon installation (a notorious difficulty with some high performance power cords). It is safe to bend, so a 2m length is very easy to install, even if you don’t presently need the entire 2m of length in application, but might foresee its use in the future.

To be complete, note that using a 3m DFPC on one component will not sound as good as powering two components with two 1.5m DFPCs (one each). The more components receiving power from their own DFPC, the better the sound very noticeably, whereas the addition of extra length to only one DFPC results in but a minor improvement. It is possible for even the most astute listeners to mix up length differences in a blind test, whereas they’re unlikely to be confused about whether one or two DFPCs are powering different components—even if those lengths are short.

Using the DFPC Original, Signature and Reference in combination

If you're considering using a combination of the DFPC Original, Signature or Reference in your system, for best cost-effectiveness and best overall performance, follow these rules:

A. If you can’t get the DFPC Reference or Signature, get the DFPC Original.

B. As discussed above, apply first at the source, then amps, then preamp, then power distribution, then phono motor.

C. To achieve higher cost-effectiveness, it is better to use multiple DFPC Originals than a smaller number of DFPC Signatures. Same goes for multiple Signatures rather than a smaller number of Reference power cables.

Upgrade option available

We offer an attractive and friendly upgrade option. For details, please write Louis Motek at

[email protected].

There is only one correct way to connect a DFPC to an outlet. Every DFPC has small "L" and "N" markings on its IEC connector, which correspond to

live and

neutral. Sometimes, a wall socket's internal electrical connections are reversed. It is important to ensure that this is not the case. You can test this with a safe and simple $5

receptacle tester from your local electronics store.

Electricians without audiophile experience might scoff at this, claiming that with AC power there cannot possibly be a difference in sound quality either which way around, as long as the circuit is closed. We urge the audiophile to please heed this instruction, as it is crucial to achieving top performance. We purposely incorporate this design aspect into all DFPCs. For best results, heed the L and N rule.

This holds especially true for those who live in countries where the European Schuko outlet is used. If you can invert the L and N lines simply by inserting the plug into your symmetrical outlet the other way around, you must first investigate your outlet to determine which contact is the L and which is the N. Then make sure you’re plugging in the DFPC such that the contact pin on the Schuko cable plug, the one

not marked

CE, is the one which receives the L line. Only this way can you be sure that the L line exits the cable’s IEC ending through the hole marked L. This is of utmost importance for top performance.

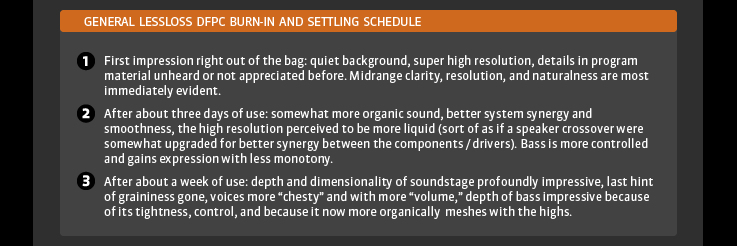

As with all audio equipment (cables included), the better the gear, the more readily the burn-in process is revealed. Burning in your DFPC will enable you to more fully appreciate all the improvements that the DFPC offers.

Over several years, we’ve received much feedback from audiophiles relaying their DFPC burn-in experience. Today, we can say with confidence that the following generally describes what to expect:

This is a general guideline to give you an approximation for what you can expect with the DFPC. We all have our own wording to explain our experience of these differences, but on average, feedback from our customers has closely described the three stages of qualitative sound development described above. Of course, these won’t be perceived as discrete steps. All the while, performance will continue to become more sublime.

Part of the reason why the burn in is so easily audible is because of the very low noise floor the cable provides. On such a silent backdrop, more subtle things are noticeable than ever before. This includes musical nuance as well as changes in equipment performance over time.

The DFPC tends to burn in more quickly on higher current-drawing equipment, such as power amps. Thus, if the final application will be to a component which consumes power sparingly (a CD player, say), you may choose to use the power cord on the power amp for a couple weeks before applying it to the other component for good. This is just in the interest of speed. Some have used specialized cable burn in devices to good effect. Using DFPCs directly where they’re intended to be used is also just as good; the burn in period may take somewhat longer, but for many, observing and enjoying this happen is part of the mystery and fun.