New C-MARC power cord! The best just got better!Friday 01 December, 2017

Dear Esteemed Customers,

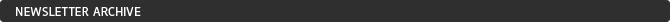

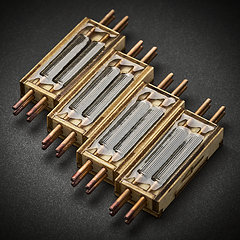

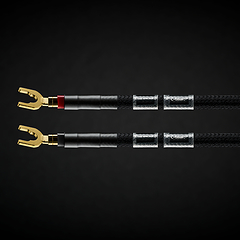

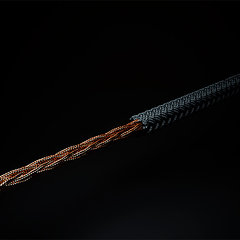

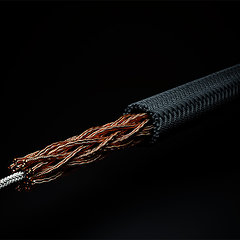

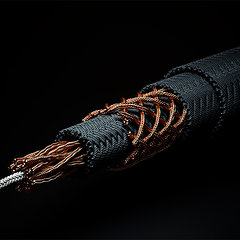

Introducing the C-MARC™ Super-cable! Starting this week, LessLoss will begin making even better C-MARC™ power cords. The currently produced C-MARC™ power cords are based on the Triaxial version of the C-MARC™ bulk cable, with 2.3mm^2 cross section for the Live line, 2.3mm^2 for the Neutral line, and 0.86mm^2 for ground. Now, with this new design, we are taking C-MARC™ to the extreme by creating a hand braided power cord with a huge 4.6mm^2 cross section for each of the three lines. This power cord features water protection and is of lightweight construction. The sound quality achieved positively introduces an entirely new level of sonic performance which LessLoss customers have never before experienced. It's exciting and not overly expensive. These do take a lot longer to produce and cost a substantially larger amount in terms of base cable from which they are made, but we no longer need to spend to develop the cables so the math works out! To make the new super-cable, three runs of C-MARC™ coaxial cable are required with a length ratio of about 1.22:1, so to make a 2m power cord we are looking at 7.5m of raw material of the C-MARC™ coaxial cable. Once heard, it is simply breathtaking and there is no going back. Every existing LessLoss customer will be offered a very attractive, quick and easy upgrade option at the end of this Newsletter. You don't even need to pay now, all we need is your commitment and you'll be registered in our production queue. How we make them: a hands on look at the inner construction C-MARC™ has two types of cotton core material which ensure micro-vibrational silencing of the lines. The innermost core is 100% unbleached, natural fibre cotton braid. Around this is braided the first 2.3mm^2 assembly of individually lacquered Litz wires in dual fractal replication. Then comes a second layer of natural cotton fibre, mercerized and dyed black. A second 2.3mm^2 Litz wire assembly surrounds it, upon which a thin, transparent moisture protection layer is added. We use three such coaxial cables in the construction of the new C-MARC™ power cable. To prepare the endings, much careful work is needed. The magic happens when all strands remain unbroken, and are electrically connected. To get there, we need to carefully unbraid a portion of each ending. There are six such individual endings to work with on this cable. Above we see the 16 individual braids which make up the outer Litz assembly. Those braids are extremely tiny and tightly woven. This cable is probably the slowest production cable in the world at this time. The braiding step is only a fraction of a millimeter. The cotton must be removed while taking extreme care not to cut any of the 384 individually enameled strands of copper. There is no rushing allowed. Once we are at this configuration, we can double check to make sure all stands are intact. (No, we don't check and certify each of the 384 strands individually with a tester. In that case we'd be looking at a $20k cable. We simply work extremely carefully and with sincere dedication to our task to maximize performance.) This step was perhaps unnecessary but it is indeed a beautiful object, so why not. This is in fact very necessary. The innermost cotton braid must also be removed in order that the tinning process is successful and reliable. In order to get to it, everything needs to be spread out like a flower. 4.6mm^2 Litz wire would never fit into a wall plug, so in order to make the electrical connection with both of the fractal braids (each is 2.3mm^2), we need to cut the outer braid shorter than the inner one. Now we are ready to combine the two braids into a single conductor. This way we can fit the contact into the plug and clamp down on it very securely and reliably. Now we go to the tinning pot, use a special liquid flux, and at several hundred degrees, we burn off the lacquer from the ends, replacing it with a thin layer of solder. This ensures all connections of the Litz wires are made and allows electrical contact to be made with the wire assemblies. Then we hand braid three such prepared wires until we get to the end of the cable. Again we have to prepare all three remaining ends, as above. The new results: it is a profoundly accurate, beautifully sounding product, the likes of which we have not yet heard. Works wonders on both high current and low current gear. There is so much involvement and believability from the sound, it is even uncanny! Price The price is set at 1148 USD for lengths up to 2m. Additional lengths come with nominal surcharges. Can I upgrade my existingC-MARC™ power cable? Sure! Many of you purchased the original Triaxial C-MARC™ power cord using pre-order Credits. Thus your actual cost was 490 USD. We will give anybody the same in full(!) for upgrading to the new 3 x 4.5mm^2 version. To be clear: this means that an upgrade is 1148 - 490 = 658 USD, including shipping. This offer is valid until December 31, 2017, which is 4 weeks away. How about DFPCs? Can existing LessLoss customers upgrade DFPCs to this 'Super-cable?' Yes. The same conditions apply. How about DFPCs, even if I did not purchase from LessLoss directly? Yes, you're welcome to. What do I need to do? Let me know via return email! Louis Motek will gladly help you out with your upgrade. Best regards, Louis Motek | LessLoss.com

|

- Products

- Power Cables

-

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

- Loudspeaker Cables

- Interconnect Cables

-

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs / Tax

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-

Beware of Fakes

Beware of Fakes