New Product Announcement from LessLoss AudioSunday 09 June, 2019

Esteemed LessLoss Customers,

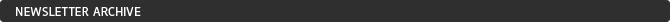

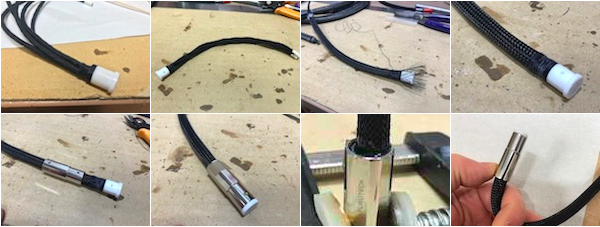

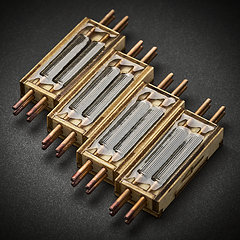

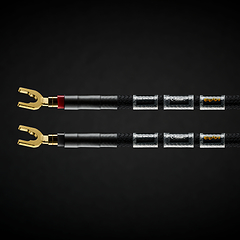

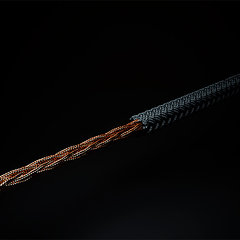

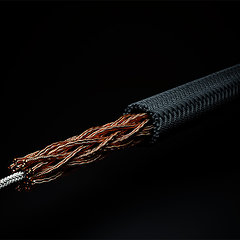

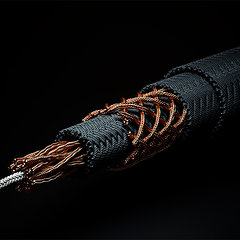

This will be great news to all vinyl fans. New C-MARC™ Phono Cable from LessLoss LessLoss now offers a 100% C-MARC™ based Phono Cable with 5-pin DIN connector and separately grounded shielding. There is nothing else like it. Below you will find bench snapshots. We are going to have studio images in the near future.  Price is set at 1398 USD / 1m. Additional half meter increments are 178 USD each. This is our most labor-intensive product. Below you will see what I mean because I will showcase the entire build process. It is not possible to build this cable in a single sitting. It requires two clear epoxy curing sessions, the first 24 hours, and the second 48 hours long. This has to be the most time-consuming specialty cable product on the market today, and it's all in the direct service of superb sound. The product, as do all C-MARC™ products, begins life as a precision micro-braid of hair thin (0.125mm to be precise) copper wire. Each strand of this micro-thin wire is individually lacquered with the thinnest technically possible clear enamel. This ensures that no electrical contact is made between the strands, except at the very ends of the cable.  This is a super slow production process which ensures no strands are broken or stretched. Precision machinery from Germany is used to achieve this. Through an elaborate set of steps, each slower than the preceding one, the C-MARC™ Coaxial cable is finally formed. Below you can see the structure of the individual elements which make up merely the center core of the coaxial C-MARC™ cable. You are looking at a total conductive cross section of 2.3mm^2. Remember that the signal which will be traveling down this wire comes directly off of the cartridge needle. This is the smallest and most sensitive signal in all of audio, just a few millivolts. We provide more conductivity to this micro signal than does most internal domestic home installation wiring to power things like washing machines and 2000W electric heaters. The special thing here is that the structure of the cable itself is already protecting against modern very high frequency noise, which due to the ubiquity of cell phone infrastructure and 5G Internet of Things networks is only getting worse and worse. Normal shielding does not protect our sensitive signals from this but our cable geometry certainly does and it is immediately evident in the purity of the signal transfer. If it sounds too good to be true here in writing, it is usually perceived as such even during the first listening session. Instantly, one knows one is dealing with something very special. We avoid plastics and instead use 100% natural cotton insulation. This further reduces sound coloration and smearing throughout the entire frequency range. Once the many, many hours of production of the C-MARC™ Coaxial cable is finished on the machines, the work by hand begins. This is a laborious task of preparing the endings for tinning and subsequent soldering to the very large Xhadow RCA plugs. 100% cotton string and special fast-curing glues are used to prevent shorts. Extreme care is taken that not a single of the hair thin strands are cut in the process.  The extra thick copper shielding is kept electrically floating at the RCA ends so that exclusively C-MARC™ is used for the signal and signal grounds. Once all the work is done on the RCA lengths and the RCA plugs are attached, the result looks like this:  The C-MARC™ insignia is applied with only a small amount of weather-resistant clear protective plastic.  Then at this stage we move on to the small 5-pin DIN end and the short flexible lead we need to create for this end of the phono cable. We use C-MARC™ Hook-up Wire, Small size, for this purpose. "Small" is a misnomer here of course since we are dealing with a cross section of 0.86mm^2 which is still huge considering the tiny milli-watt signals. The steps outlines below are depicted in the small pictures below: - 5 lengths are cut with temporary heat shrink holding the cotton in place. - Thin cotton string and quick drying glue is used instead. - Then the cotton is cut off meticulously, without damaging the copper strands. - Tinning takes place in the hot solder pot. - Contacts are made and soldered to the 5-pin DIN connector - Additional cotton string is hand wound to prevent shorts with the housing.  Then: - The 5 individual leads are given a slight twist and are covered with a very thin light braid of PET expandable sleeving for structure and protection. The slight springy pressure into the cotton serves further to reduce micro-vibration. Again, instead of plastics, we use cotton string to fixate the end and then trim the remainder off with sharp sears. - The metal barrel is introduced. We would never use the small set screw directly into the C-MARC™ cotton dielectric. Instead, we cover the set screw hole with protective tape and then proceed to place the DIN connector in vertical fashion. Once made stable, we complete the final task of potting the entire barrel with a special clear two-component epoxy resin. This sets slowly in 48 hours, after which we have an eternally secure, super DIN connection to our five C-MARC™ wires. - The resulting flexibility and very light weight of the short lead is perfect for installation into the most complex tonearm setups.  Now we return to the shielded C-MARC™ coaxial cables. The RCAs are already connected on one end, and the other ends must now be prepared for electrical contact. We begin by tightly wrapping our 100% cotton string to the assembly.  We unbraid a portion of the tinned copper shielding.  Skipping over several steps, similar to the ones pictured above during preparation for tinning on the RCA ends, we fast-forward to the already sculpted ends, ready for tinning.  Again, care is taken to ensure no strands are broken. The tight wrapping of the cotton ensures no shorts are made.  Now we can tin the ends, burning off the thin lacquer and making electrical contact. Both signal and ground are 2.3mm^2 cross section each. For a phono cable! This is unique.  Now we prepare the Grounding cable. it is based on the C-MARC™ Large size hook-up wire. Cross section is 2.3mm^2. The length we cut is about 20cm longer than the full length of the Phono cable. This can be customized by the customer but we find that in general this will fit most any setup every time.  We add the PET flexible braiding cover and prepare the ends with cotton string.  Both ends are tinned and one end is connected with a Xhadow spade. This can be customized if it is much too big for the customer's existing grounding provision in his phono pre.  We only apply plastics for a sturdy and reliable ending. The result is a super lightweight cable with a huge cross section and super low noise floor.  Now we are ready to join both the small flexible lead from the DIN connector to the two prepared Coaxials and the additional Grounding cable. The barrel used to hold the potting is a clear polycarbonate material, exactly the same as in our power cables' plugs. The use of plastics, where needed, should always be of the hardest type and 100% crystal clear. This ensures that little to no artificial sound coloration will result. The plug itself (seen here on the left of the barrel) is laser cut wood. This will hold the potting in place as you'll see below.  Before the barrel is set in place, all the electrical connections are soldered together appropriately. The grounding scheme is as follows: Two independent signal grounds (Left/Right channels) are 100% C-MARC™, and the additional floating shield is grounded via the extra grounding wire. At this point we are ready to vertically stabilize the barrel. Once stabilized and everything is vertically aligned...  ...we can proceed with the mixing of the two epoxy components and the potting of the electrical contacts within the barrel.  The compound is a slow-setting clear epoxy which hardens in 48 hours. It actually continues to harden long afterwards but 48 hours is enough in order to be able to handle it.  Once hardened, this will ensure life-long stability of the contacts and a robust cable you can throw around indefinitely. We paint the wood black and cover just the barrel with thin PVC.   At this point the cable is completed. The four ends look like this:  They are: - Two Xhadow RCA plugs, Large sizes (same type we use in C-MARC™ RCA cables) - One Xhadow high performance Spade - One very fine Furutech 5-Pin DIN connector  Then we do a final test, look it over, and pack it up for shipping. This is how you will get it.  Review in progress Right now, this cable is being reviewed by Danny Kaey in his big system. He is so excited he has already ordered three of these cables for his three separate tonearms. He is kind enough to welcome your enquiries into the sound he is getting from these incredible cables. Feel free to connect with Danny Kaey ([email protected]) for more opinion on our latest C-MARC™ phono cable. You can follow his audio journeys at Fidelity Magazine and AudiophileStyle. Purchase yourself the C-MARC™ Phono Cable and never look back again. We don't have the web shop set up for this just yet, but until then I'll accept your order via email and will gladly send ordering instructions to you personally. Just write to me on: [email protected] and we'll take care of it! Here's to great analogue sound! Regards, Louis Motek | LessLoss.com |

- Products

- Power Cables

-

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

- Loudspeaker Cables

- Interconnect Cables

-

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs / Tax

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-

Beware of Fakes

Beware of Fakes