UPDATE: Firewall for Loudspeakers Production, or How DARPA missed the Audiophile BoatSunday 28 July, 2019

Dear esteemed Customers,

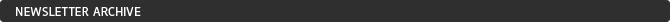

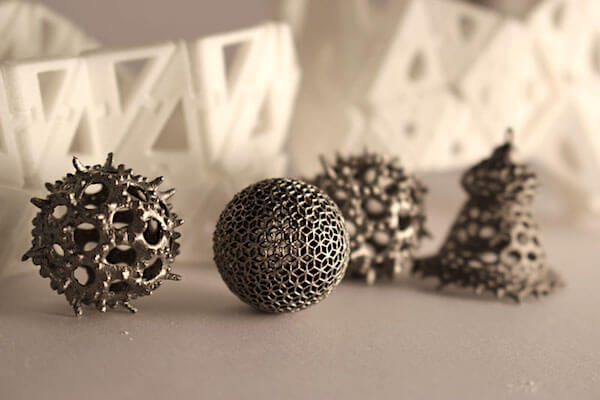

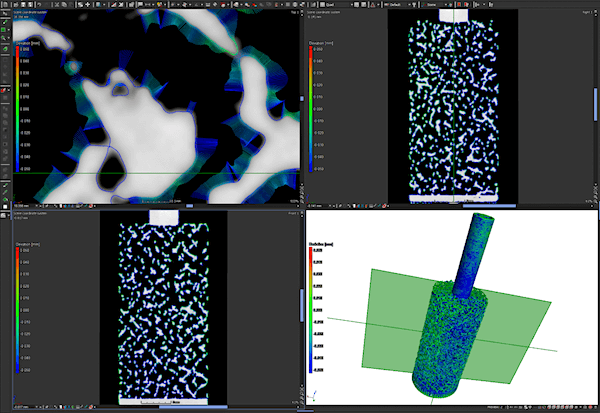

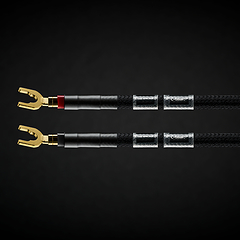

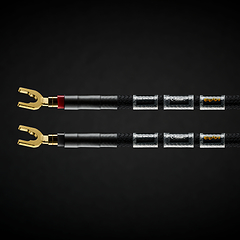

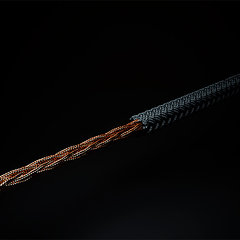

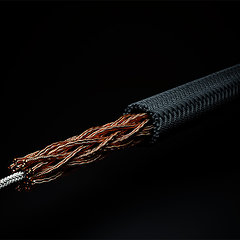

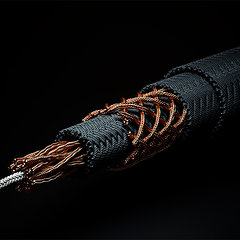

Thank you to all who have responded so far with regards to the Firewall for Loudspeakers launch. Additional responses are still trickling in as more and more people read the news. Here is a link for anyone who may have missed the last Newsletter announcement about our latest, most advanced product, the Firewall for Loudspeakers. We look forward to more responses which will enable us to lower your introductory price yet further! Years of Effort The Firewall has gone through a lot of research and development since its inception. What began as a novel idea about implementing Skin-filtering by exploiting the naturally occurring Skin-effect of current running through a wire has been expanded upon many times since its inception. Today we are actually using field structuring around the conductor in unique ways. The Firewall 64X is a LessLoss proprietary technology, based on precisely positioned directional metallic particles within a thermoplastic carrier. The result becomes kind of a micro-transformer. Kind of a ferrite core filter. Kind of a directional set of A/C diodes. Very much kind of a near field Blackbody for signals. That pitch black background, so important to stable "3 AM" type sound quality, is getting set to a higher and higher bar at every step of our way. People keep asking, 'Can it really get any better than this?' Answer: you bet! When the Firewall for Loudspeakers is connected to the signal at the speaker terminal, it brings a cosmic change to the sound quality. How do we make it? Well, we don't. We assemble it. The core production of our proprietary technology is carried out by a certified specialty lab by men in what can only be described as hazmat suits. This is actual photography from their state-of-the-art facilities:  The above machine makes the proprietary Firewall components. How is it done? It's done by laser. Direct Metal Laser Sintering (DMLS), also known as Laser Powder Bed Fusion (LPBF), is an Additive Manufacturing (AM) technique designed to use a high power-density laser to melt and fuse metallic powders together. This process has the ability to fully melt the metal material into a solid three-dimensional part, unlike Selective Laser Sintering (SLS). SLS was originally developed in the mid-80's under sponsorship of DARPA. This process has the disadvantage that resulting parts have porous surfaces. Expensive post-processing methods such as Hot Isostatic Pressing are required to reduce the pores. In other words, the parts must be placed in a high pressure argon atmosphere and raised in temperature, then quickly and uniformly cooled, in order to achieve stability and reliability. More advanced than DARPA? We are using an even more advanced system, called Direct Metal Laser Sintering (DMLS). Research on this process began in 1995 as a German research project at the Fraunhofer Institute. This new technology was first commercialized in 2000. From the Wikipedia entry for Selective Laser Melting: (the link is here.) "Since the components are built layer by layer, it is possible to design organic geometries, internal features and challenging passages that could not be cast or otherwise machined." Below are actual objects made by our production partners using this innovative, state-of-the-art DMLS process. What's fascinating about the design freedom enabled by this advanced technology is that you can make objects nested into objects, with surfaces and internal voids which would otherwise be absolutely impossible to make.  In fact, you could, if you wanted, make all of the above objects placed, quite literally, inside one another. Meshed with one another. Even turned Inside out. This was not possible before. Hey, we can use this! That's where LessLoss comes in. Our solutions are so uncommon, that even the 3D laser production guys had to produce at least 80 prototypes before they got a hang on nuances such as repeatability, precision, scale and visible and non-visible surface demands. They use the most advanced software available such as Solidworks, so going back and forth from accountably accurate changes was only a matter of fortitude.  The computer process slices the 3D CAD file data into many ~20 micrometer thick layers. The thin layers are, one by one, selectively smelted by the laser which is located in a tightly controlled atmosphere of argon gas. Believe me, this is no desktop operation. Oxygen levels must be kept lower than 500PPM to prevent explosion. The high-power ytterbium fiber laser beam is literally hundreds of watts strong. The laser energy is intense enough to permit full welding of the particles to form solid metal, without creating a porous internal structure.  What is the product compatibility, and how will it look? The new Firewall for Loudspeakers will be made of four separate units. Each unit will have a speaker terminal which accepts both banana and spade connectors from your existing loudspeaker cable. The terminal will be housed in a small wooden enclosure, each smaller in size than the existing Firewall 64X for power. From here, a short C-MARC™ loudspeaker cable umbilical, highly flexible, will extend to a termination of either banana or spade (you choose which for your application). This will connect directly to your loudspeaker's terminal. One complete set of this new Firewall for Loudspeakers will consist of four such separate units. One for Left positive, one for Left negative, one for Right positive, and one for Right negative. All will be marked clearly for easy installation. What's the projected price range? We are talking, most likely, about a just-over-1000 USD retail price point for all four units of one stereo set. (This means just-over-250 USD per terminal.) With an Early Bird pricing as aggressive as possible, largely depending on response numbers, it is in your hands to lower the initial discounted launch price. The discount window depends entirely on participant numbers. It will be best for everyone here on this mailing list if we get the largest amount of positive responses. So, here's what I want you to do. Please respond to this email (by email response) with just these answers (please answer all three of them): --- I am expressly interested in the new Firewall for Loudspeakers Early Bird offer in the next few weeks. YES or NO --- I am expressly interested in the new Firewall for Loudspeakers product but need about 5 or 6 weeks to prepare, and will. YES or NO --- I am expressly interested in the new Firewall for Loudspeakers product but need about two or three months to prepare, and will. YES or NO Once the data is in, we will be able to calculate and lock the retail pricing and the Early Bird offer, and then we can send out a follow-up inquiry and work out the release schedule. As always I will keep you informed at every step of the way. So, please, do participate at this stage with just the answers! Everyone working together like this can bring everybody's speakers to perform sonic miracles, at super pricing! Thank you for your time and interest! Regards, Louis Motek | LessLoss.com |

- Products

- Power Cables

-

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

C-MARC™ Prime

The must have foundation for any sound system today.

From

$

486

-

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

C-MARC™ Classic

The unique super-cable power cord everyone's talking about.

From

$

1148

-

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

C-MARC™ Classic Entropic Process

The peerless, advanced Classic masterpiece.

From

$

1934

-

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

C-MARC™ Stellar Entropic Process

The crown jewel for highest performance power connection.

From

$

2450

-

- Loudspeaker Cables

- Interconnect Cables

-

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

RCA C-MARC™

Cotton-clad true Litz • Whopping 2.3mm2 polarities

From

$

850

-

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

RCA C-MARC™ Entropic Process

Our finest RCA cable • Polished Wenge barrels

From

$

1428

-

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

XLR C-MARC™

A hand-braided cotton-clad unique Litz construction

From

$

950

-

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

XLR C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

1615

-

- Digital Cables

-

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

RCA Digital C-MARC™

Cotton-clad unique Litz design • Made only by LessLoss

From

$

510

-

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

RCA Digital C-MARC™ Entropic Process

Possibly the most subtle digital cable on the planet

From

$

858

-

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

XLR Digital C-MARC™

Featuring a whopping 3 x 2.3mm2 Litz construction

From

$

570

-

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

XLR Digital C-MARC™ Entropic Process

Stratospheric performance for the audio connoisseur

From

$

969

-

- Grounding Cables

- Bulk Wire and Cable

- Signal Conditioners

-

Firewall for Loudspeakers

Firewall for Loudspeakers

C-MARC™ Plug-and-Play Speaker signal conditioning like you've never imagined From $ 1656 -

Firewall for Loudspeakers

Firewall for Loudspeakers

DIY version for Self-Installation For the Do-It-Yourself project enthusiast • Solder yourself From $ 800 -

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

BlackGround 8x/10x Speaker Base

Plug-and-play loudspeaker signal conditioner

From

$

3096

-

- Power Conditioners

-

Firewall 640x

Plug-and-play solution for any powered gear

Firewall 640x

Plug-and-play solution for any powered gear

C-MARC™ Entropic Process and standard lead versions From $ 654 -

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

Firewall 640x DIY for Self-Installation

Self-solder and save!

From

$

320

-

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

BlackGround DIY

Voltage-ground interface for a variety of applications

From

$

446

-

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

BlackGround 6x/10x Power Base

Plug-and-play power conditioner

From

$

2350

-

- Power Distributors

- Equipment Feet

- Field Conditioner

- DACs

- Power Cables

- Reviews

- This is definitely the cable to go for. It will almost literally blow your mind. – March 2012, Puresound Magazine

-

I was intrigued by the unanimously positive reviews garnered by these products ...

– by user Raymond Eye

Leaves you speechless

Sensational cables

BEST purchase I've made

Top notch performance

It's a steal

Musical... liquid... 3D

It's not subtle

More than an upgrade

Best I've heard so far

Stellar service

Sounds like a new system

Much more lifelike

Emotional flow

Overwhelming results

More dimensional

Sound is transformative

We were all astounded

Transformed my listening

Sounds so cohesive

Emotionally engaging

- Where to Start

- Free Newsletter

- Newsletter Archive

- B-Stock Alerts

- Shopping Tools

-

Shipping

- Free Shipping Learn about our international shipping policy

-

Return Options

Our satisfaction guarantee

and return policy -

Customs / Tax

UPS expedites local

customs clearance

-

Transaction

- Conditions of Sale Agreement for a smooth business transaction

- Privacy Policy We pledge to keep your information private

-

Terms of Use

Business policies

and agreements

-

Account

-

- Contact Us

-

Meet the Designers

-

- Care to share of your personal experience with our products? We'd be happy to post it!

- Want to learn more about our activities? Our Newsletter is both free and spam-free.

hi-res photos, brochures

logos, press releases, and

print-friendly PDF downloads. -

Contact Us

Connect with Us

-

Beware of Fakes

Beware of Fakes